HONSEL fastens. Cold forming, that is and has been the core business of HONSEL for decades. All common materials such as steel, aluminium, stainless steel, copper and brass can be headed.

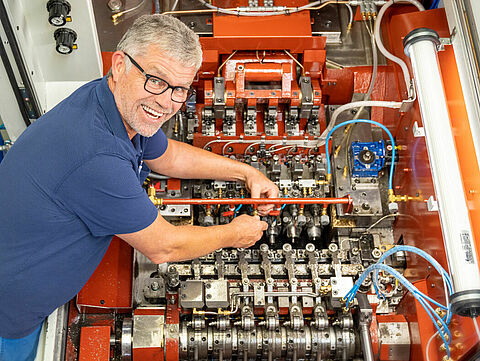

HONSEL production sites are among the most modern production facilities for fasteners.

Short routes and a large number of in-house further processing and finishing options are your guarantee for maximum flexibility. On more than thirty ultra-modern 5 or 6-stage headers, we bring wire of up to 20 mm in diameter into shape.

The production capacities are all designed for 3-shift operation. Transport and material supply routes are optimised and just as (partly) automated as the in-house transportation and delivery to the customer.

Another elementary factor for smooth production is access to a well-filled starting material and wire stock at the site at all times.